| | Custom Enamel Pin Metal Pin Lapel Pin |

| | Zinc Alloy / Iron / Brass etc.

|

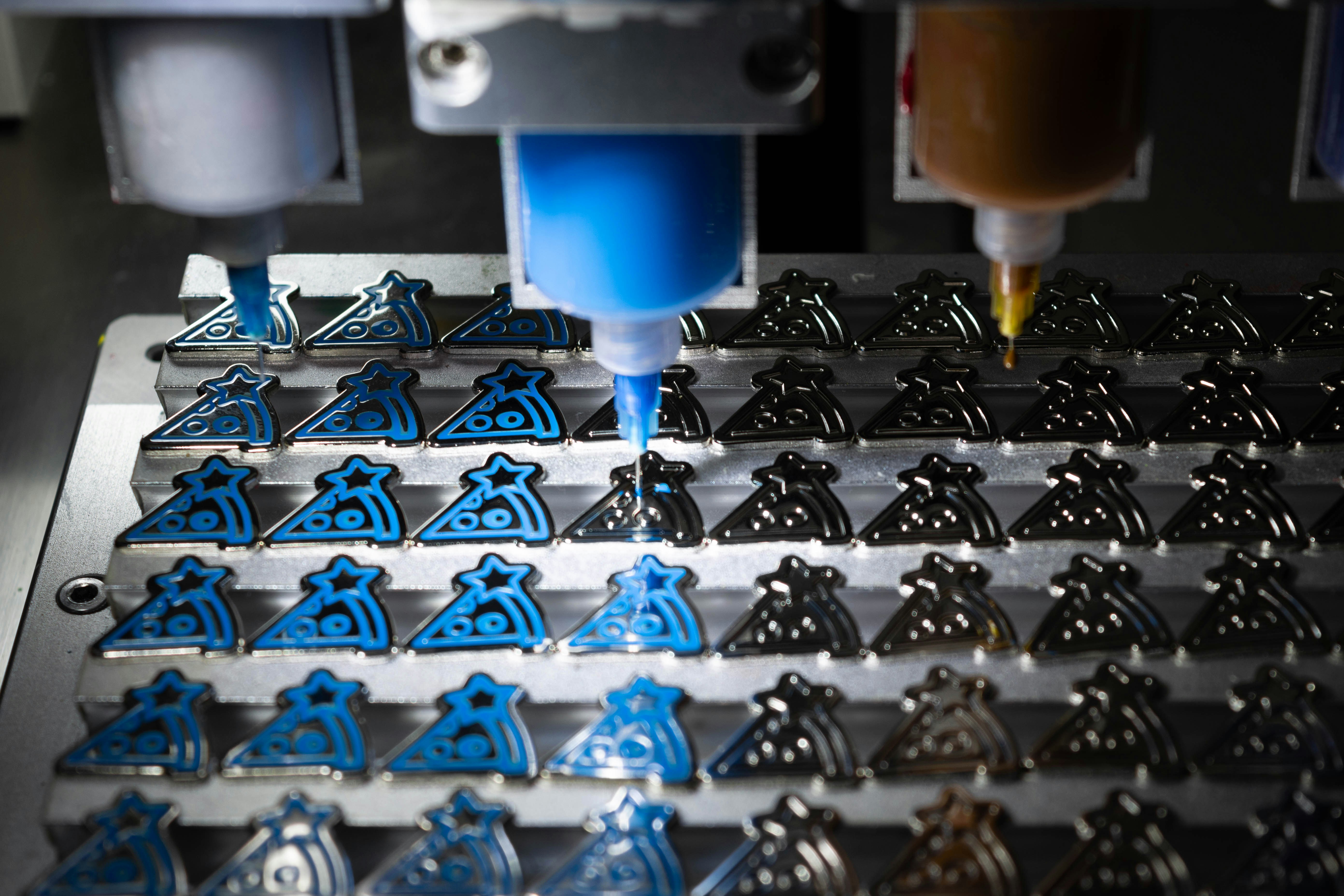

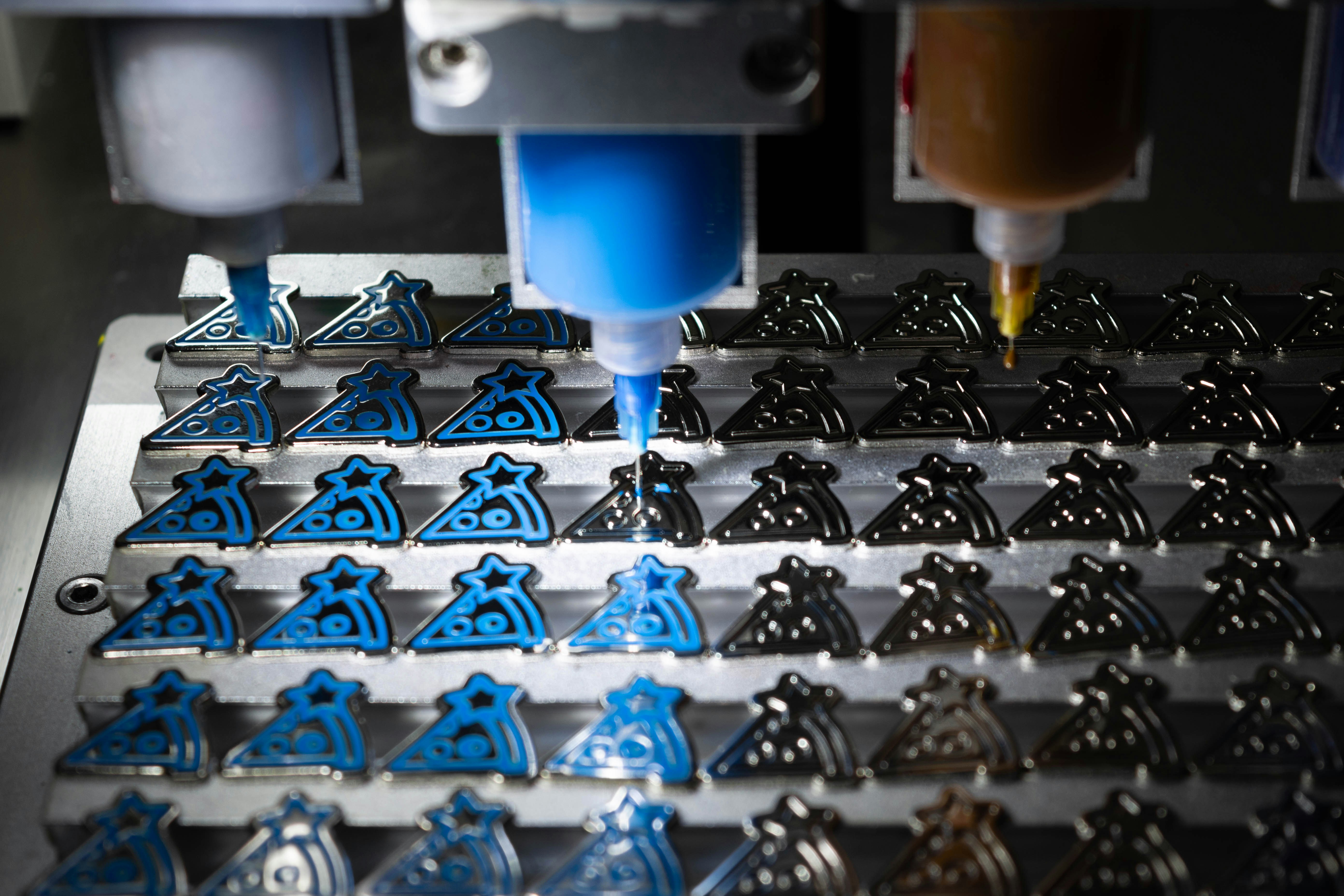

| | Soft enamel, Hard enamel ,screen printing, Offset, 3D |

| | 0.5inch,1inch,1.25",1.5",2inches,2.5",3".3.5"...etc(According to customer request)

|

| | Gold/Silver/Nickel/Copper/Rose Gold/Rainbow/Dye metal/ Antique plating etc. |

| Attachment | Rubber/Jewelry/Deluxe/Butterfly clutch/Safety Pin/Magnet/Key chain etc. |

| Packing | Backing Card/OPP/Bubble bag/Acrylic box/Paper box etc. |

| MOQ | 10pcs |

| Lead Time | Sample: 7~10days,Mass production: 10~15days |

| Payment | 50% advance payment to start production |

| Shipment | FedEx / DHL / UPS / TNT etc. |

What kind of badge products meet environmental protection requirements?

In the current social environment where environmental awareness is increasing, the environmental protection requirements of badge products are also receiving more and more attention.

1. Material selection: Environmentally friendly badge products usually choose materials that meet environmental standards, such as recyclable materials, lead-free materials, etc. Avoid using harmful substances that harm the environment and human body.

2. Production process: The production process of environmentally friendly badge products should minimize pollution to the environment and avoid the use of harmful chemicals and high-energy consumption processes etc.

How do customers choose high-quality badge products? :Edge processing

1. Smoothness: The quality of edge treatment can be felt by touching the edge. The edge of a high-quality badge product should be smooth and without obvious burrs or jaggedness. Products with fine edge treatment are usually more comfortable and durable.

2. Consistency: The edge treatment should be consistent across the edge of the badge product, without obvious irregularities or protrusions. Consistent edge treatment can enhance the overall beauty and texture of the product.

3. Process details: Pay attention to the process details of edge treatment, such as whether the chamfering, polishing and other treatments of the edge are fine. High-quality badge products usually spend more effort and craftsmanship on edge treatment, presenting a more refined effect.